Fine Chemical Industry

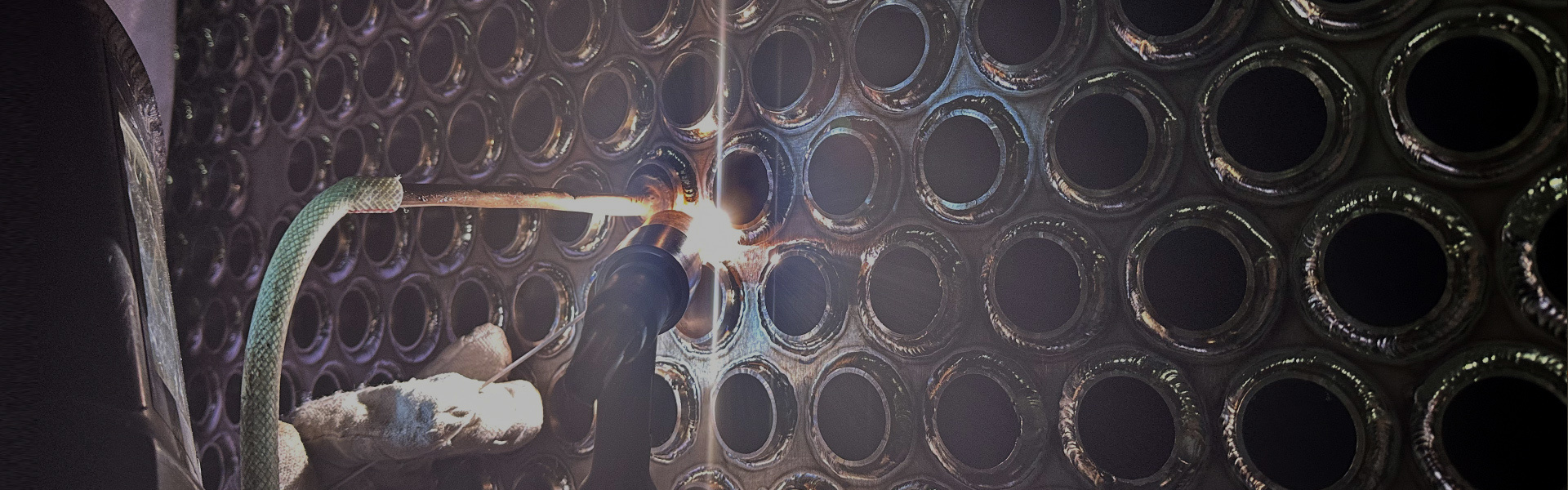

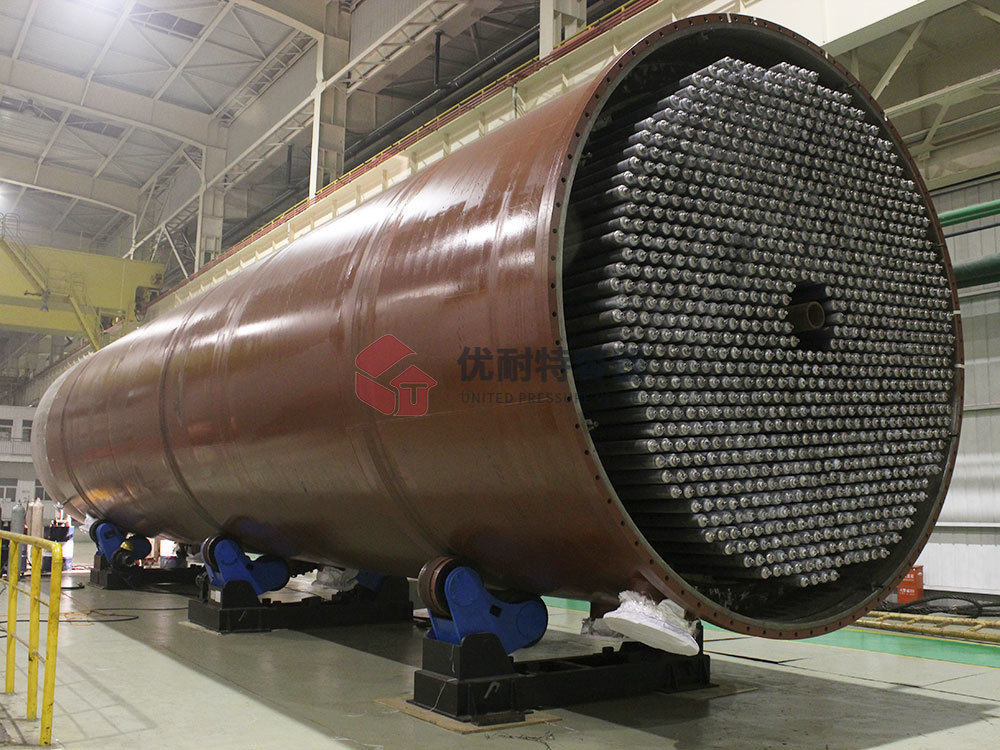

The pressure vessel equipment produced and manufactured by our company is dedicated to addressing corrosion-resistant needs in chemical erosion processes. We provide complete sets of equipment for the fine chemical industry, such as oxidation reactors, heat exchangers, crystallizers, towers, condensers, and more. The equipment is primarily used in industries or fields such as acetic acid, formic acid, oxalic acid, polyoxymethylene,polyformic acid, purified terephthalic acid, dye intermediates, pesticide and pharmaceutical intermediates, MMA, amino acid projects, etc.

We are dedicated to delivering energy-efficient, environmentally sustainable equipment for the fine chemical and petrochemical industries with the support of mature technologies.

As early as 1986, the company successfully applied titanium materials to vacuum salt production process systems. In 2001, we accomplished the first domestically produced crystallizer condenser for Jiangsu Yizheng Chemical Fiber. Since then, we have continued to achieve excellent performance in PTA projects. Currently, the maximum heat exchange area of our titanium heat exchangers is 12,679 m².

We are proud to have been the first to apply zirconium and zirconium alloys in resorcinol plants. The zirconium clad reactors developed by our company have met both domestic and international standards, marking the first successful application of the hydrolysis method for continuous production of resorcinol. This achievement has led to technological advancements in the industry with considerable economic and social benefits.

For the application of nickel and nickel alloy materials, the company and the group have jointly developed China’s first Monel 400 double falling film crystallizer. This equipment features a significant temperature range and demands extremely high machining precision during the manufacturing process.

UPV has deep expertise in the design, manufacture, inspection and testing of equipment including:

|

|

|

|

|

|

|

Distillation columns |

Packed tower |

... |

|

UPV manufactures equipment made of carbon steel, high alloy steel, nickel and nickel alloys, titanium and titanium alloys, zirconium and zirconium alloys, tantalum and tantalum alloys, niobium and niobium alloys.

The pressure vessel equipment produced and manufactured by our company is dedicated to addressing corrosion-resistant needs in chemical erosion processes. We provide complete sets of equipment for the fine chemical industry, such as oxidation reactors, heat exchangers, crystallizers, towers, condensers, and more. The equipment is primarily used in industries or fields such as acetic acid, formic acid, oxalic acid, polyoxymethylene,polyformic acid, purified terephthalic acid, dye intermediates, pesticide and pharmaceutical intermediates, MMA, amino acid projects, etc.

We are dedicated to delivering energy-efficient, environmentally sustainable equipment for the fine chemical and petrochemical industries with the support of mature technologies.

As early as 1986, the company successfully applied titanium materials to vacuum salt production process systems. In 2001, we accomplished the first domestically produced crystallizer condenser for Jiangsu Yizheng Chemical Fiber. Since then, we have continued to achieve excellent performance in PTA projects. Currently, the maximum heat exchange area of our titanium heat exchangers is 12,679 m².

We are proud to have been the first to apply zirconium and zirconium alloys in resorcinol plants. The zirconium clad reactors developed by our company have met both domestic and international standards, marking the first successful application of the hydrolysis method for continuous production of resorcinol. This achievement has led to technological advancements in the industry with considerable economic and social benefits.

For the application of nickel and nickel alloy materials, the company and the group have jointly developed China’s first Monel 400 double falling film crystallizer. This equipment features a significant temperature range and demands extremely high machining precision during the manufacturing process.

UPV has deep expertise in the design, manufacture, inspection and testing of equipment including:

Distillation columns

Packed tower

...

UPV manufactures equipment made of carbon steel, high alloy steel, nickel and nickel alloys, titanium and titanium alloys, zirconium and zirconium alloys, tantalum and tantalum alloys, niobium and niobium alloys.