Advantages of Tantalum Heat Exchanger

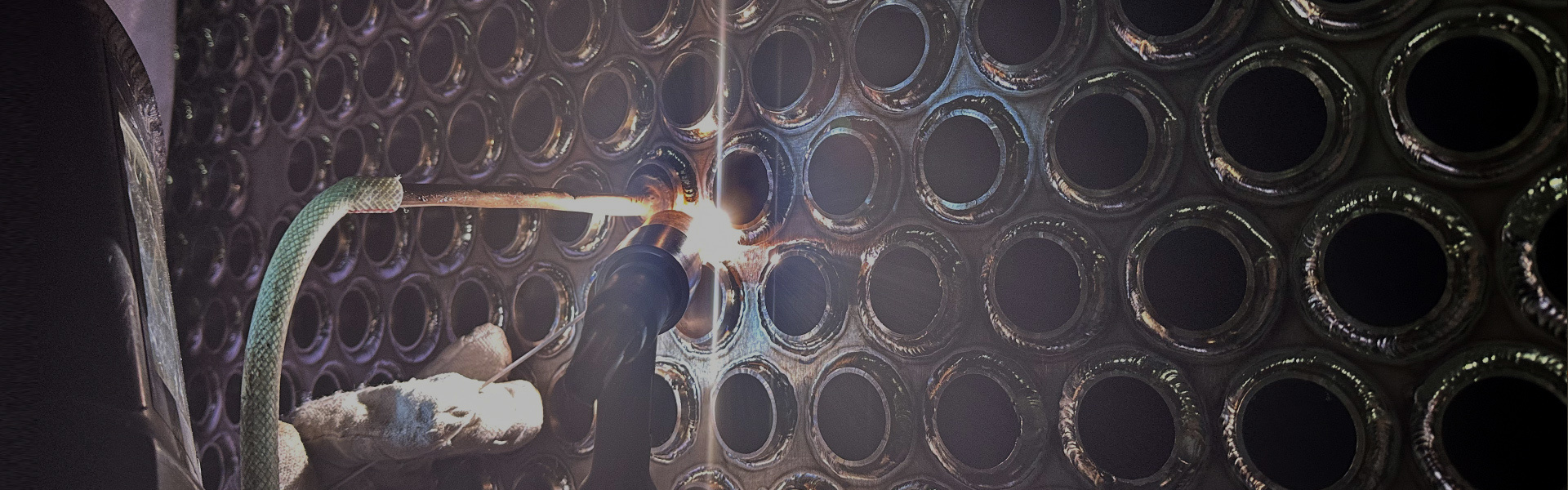

Acid pickling Industry

Acid pickling is a method of cleaning metal surfaces and a critical step in ensuring the quality of steel products, which involves using acid solutions to remove oxide scales and corrosion from the surface of steel.

Types of acid pickling solutions: Hydrochloric Acid (HCl), Sulfuric Acid (H₂SO₄), Nitric Acid (HNO₃), Phosphoric Acid (H₃PO₄), Hydrofluoric Acid (HF), and Composite Acids.

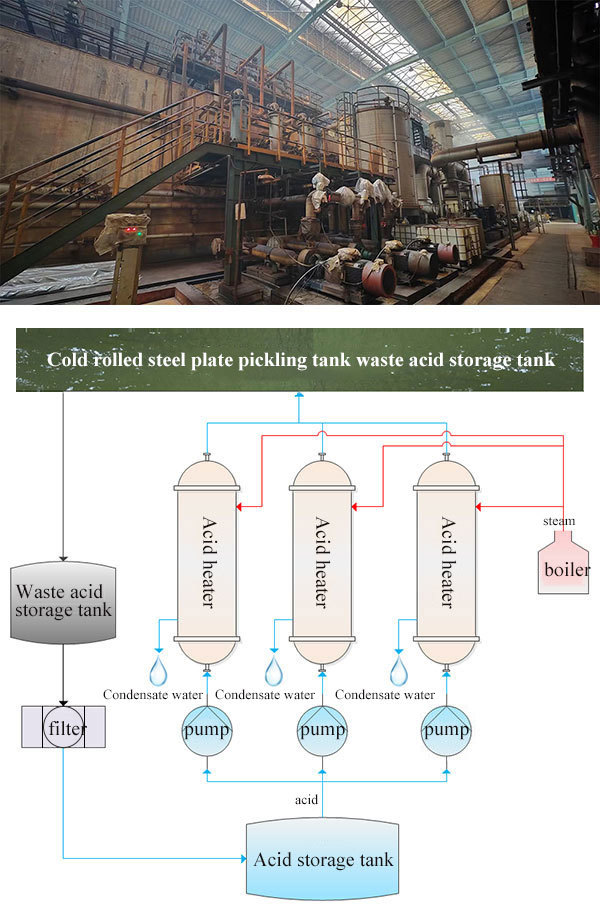

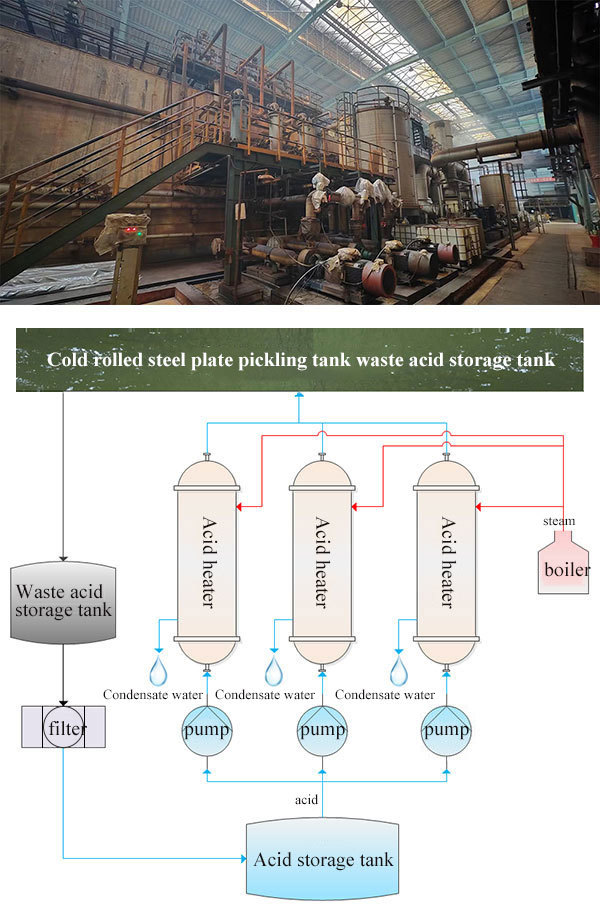

The current mainstream acid pickling process primarily uses a spray turbulent flow technique with an acid pickling tank and an acid heater. The acid heater heats hydrochloric acid to a temperature range of 75 to 85℃, which is then pumped into the pickling tank to clean the surface of cold-rolled steel sheets through spraying.

The used acid is filtered, then discharged into a storage tank, and pumped back into the acid heater for recycling in a closed-loop system.

Hydrochloric acid performs best and achieves the highest efficiency in pickling at temperatures between 75 and 85°C. However, hydrochloric acid has strong corrosiveness in this temperature range, which limits the selection of materials for acid heaters. Therefore, graphite is commonly used as the material for the acid heater due to its corrosion resistance.

In hydrochloric acid pickling, the concentration has a greater impact on the pickling rate than the temperature. When the acid concentration increases from 2% to 25%, the speed of hydrochloric acid pickling increases by about 10 times. When the temperature rises from 18 ℃ to 60 ℃, the pickling rate of hydrochloric acid increases by 9-10 times. Therefore, the temperature for hydrochloric acid pickling is generally around 80 ℃, and an acid heater is required during the pickling process.

Our recommended solution is to use tantalum equipment. Tantalum alloys have excellent corrosion resistance. Except for hydrofluoric acid, fluorine, fuming sulfuric acid, and alkali, it can withstand corrosion from almost all chemical media.

Tntalum alloy is a metallic material with a thermal conductivity of 50 W/(m·K).With excellent mechanical properties, and under the same operating conditions, a tantalum alloy heat exchange tube with a wall thickness of 0.5 mm can meet both strength requirements and heat transfer needs. Additionally, the heat exchange tubes have a large diameter and a smooth inner surface, which minimizes the risk of blockage.

Compared to graphite heaters, tantalum heaters are smaller in size and more space-efficient. Tantalum alloys offer excellent mechanical properties, which make them easy to process and resistant to damage.

By introducing tantalum heat exchangers into the steel pickling industry, UPV has effectively addressed the potential problems related to the traditional graphite block heat exchanger, helping customers achieve energy savings, emission reductions, and improvements in quality and efficiency.

1.Faster Heating Speed and Steam Savings.

2. Ensure that the temperature of the acid meets the standard in a low-temperature environment to improve the pickling effectiveness.

3.Reduces Downtime, Ensures Continuous Production, and Overall Cost Saving.

4. No sediment nor Blockage, proven effective through UPV’s thermal design and field practice.

5. High thermal conductivity and excellent corrosion resistance.

Acid pickling is a method of cleaning metal surfaces and a critical step in ensuring the quality of steel products, which involves using acid solutions to remove oxide scales and corrosion from the surface of steel.

Types of acid pickling solutions: Hydrochloric Acid (HCl), Sulfuric Acid (H₂SO₄), Nitric Acid (HNO₃), Phosphoric Acid (H₃PO₄), Hydrofluoric Acid (HF), and Composite Acids.

The current mainstream acid pickling process primarily uses a spray turbulent flow technique with an acid pickling tank and an acid heater. The acid heater heats hydrochloric acid to a temperature range of 75 to 85℃, which is then pumped into the pickling tank to clean the surface of cold-rolled steel sheets through spraying.

The used acid is filtered, then discharged into a storage tank, and pumped back into the acid heater for recycling in a closed-loop system.

Hydrochloric acid performs best and achieves the highest efficiency in pickling at temperatures between 75 and 85°C. However, hydrochloric acid has strong corrosiveness in this temperature range, which limits the selection of materials for acid heaters. Therefore, graphite is commonly used as the material for the acid heater due to its corrosion resistance.

In hydrochloric acid pickling, the concentration has a greater impact on the pickling rate than the temperature. When the acid concentration increases from 2% to 25%, the speed of hydrochloric acid pickling increases by about 10 times. When the temperature rises from 18 ℃ to 60 ℃, the pickling rate of hydrochloric acid increases by 9-10 times. Therefore, the temperature for hydrochloric acid pickling is generally around 80 ℃, and an acid heater is required during the pickling process.

Our recommended solution is to use tantalum equipment. Tantalum alloys have excellent corrosion resistance. Except for hydrofluoric acid, fluorine, fuming sulfuric acid, and alkali, it can withstand corrosion from almost all chemical media.

Tntalum alloy is a metallic material with a thermal conductivity of 50 W/(m·K).With excellent mechanical properties, and under the same operating conditions, a tantalum alloy heat exchange tube with a wall thickness of 0.5 mm can meet both strength requirements and heat transfer needs. Additionally, the heat exchange tubes have a large diameter and a smooth inner surface, which minimizes the risk of blockage.

Compared to graphite heaters, tantalum heaters are smaller in size and more space-efficient. Tantalum alloys offer excellent mechanical properties, which make them easy to process and resistant to damage.

By introducing tantalum heat exchangers into the steel pickling industry, UPV has effectively addressed the potential problems related to the traditional graphite block heat exchanger, helping customers achieve energy savings, emission reductions, and improvements in quality and efficiency.

Advantages of Tantalum Heat Exchanger

1.Faster Heating Speed and Steam Savings.

2. Ensure that the temperature of the acid meets the standard in a low-temperature environment to improve the pickling effectiveness.

3.Reduces Downtime, Ensures Continuous Production, and Overall Cost Saving.

4. No sediment nor Blockage, proven effective through UPV’s thermal design and field practice.

5. High thermal conductivity and excellent corrosion resistance.