The list of material applications is as follows

Material Applications

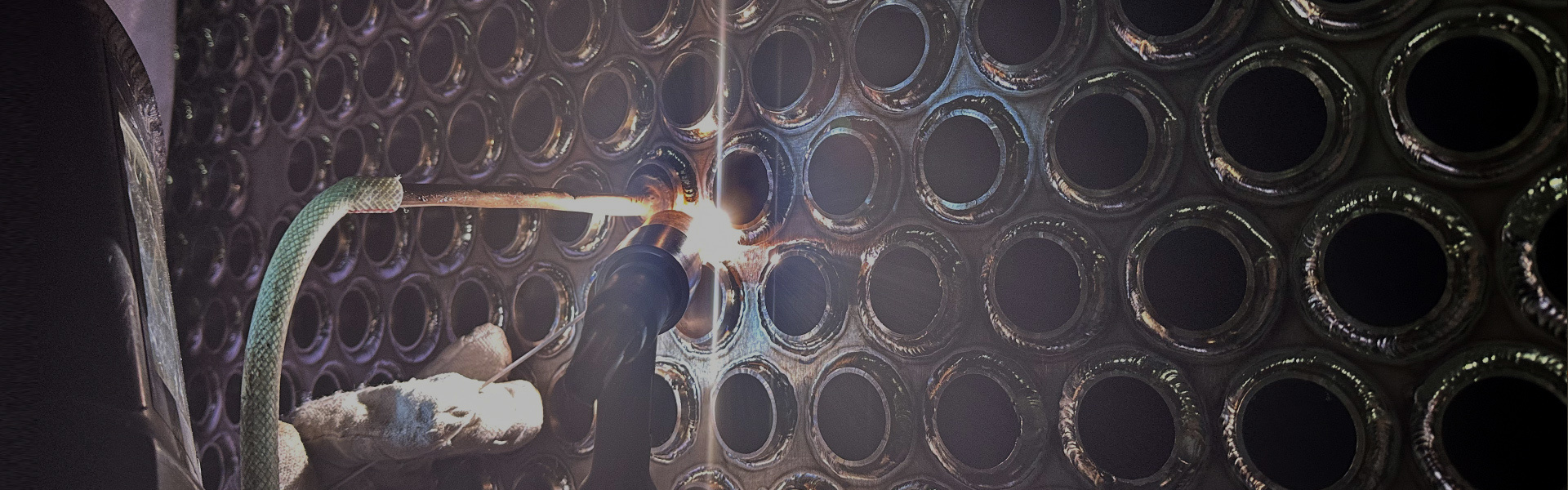

Leveraging our deep material expertise and over 50 years of research experience, we offer specialized metal application solutions for special corrosive environments.

UPV excels in the R&D, design, and manufacturing of high-end equipment utilizing non-ferrous metals such as nickel, titanium, zirconium, and tantalum, along with various stainless steels. We have established production lines for rare metal equipment and clean manufacturing of nuclear chemical equipment, achieving an annual production capacity of 1,000 sets of rare metal equipment.

UPV is committed to delivering efficient, high-temperature resistant, and corrosion-resistant reactors, heat exchangers, towers/columns, storage tanks, piping components, and accessories to help customers achieve the goal of increasing production, saving energy, and reducing costs.

Ensuring customer value is our top priority. Our investment in R&D, coupled with our accumulated capabilities, is the fundamental guarantee for continuously delivering value to the market and our customers. It is also the core of our sustained competitive advantage.

|

|

Titanium materials Density:4.51g/cm3 Melting point:1660℃ Titanium has a low density, high mechanical strength, and excellent corrosion resistance. At room temperature, titanium is resistant to dilute hydrochloric acid, dilute sulfuric acid, nitric acid, and dilute alkaline solutions. However, it is affected by hydrofluoric acid, hot concentrated hydrochloric acid, and concentrated sulfuric acid. The most common grades of pure titanium and alloys include Gr.2, Gr.5, Gr.7, Gr.12, and Ti-6Al-4V. The corrosion resistance of titanium is primarily due to the formation of a dense titanium dioxide film when exposed to atmospheric oxygen. While this oxide film protects titanium from acid corrosion, it offers no protection in strong oxidizing media without moisture, such as dry chlorine gas and anhydrous fuming nitric acid.

|

|

|

|

Zirconium Materials Density:6.499g/cm3 Melting point:1852℃ At room temperature, zirconium forms a protective oxide film that prevents reactions with most atmospheric gases. • At 200°C, zirconium reacts with oxygen. • At 300°C, it reacts with hydrogen. • At 400°C, zirconium begins to react slowly with nitrogen. • At 800°C, the reaction with nitrogen becomes more rapid. • At approximately 500°C, zirconium reacts with carbon monoxide (CO) and carbon dioxide (CO₂). Zirconium materials are primarily used in industries such as formic acid and acetic acid. Zirconium is reactive metal with excellent corrosion resistance to most acids (including alkali solution, salt solution, etc.) because of its dense oxidation film. Zirconium only undergoes severe corrosion in media such as hydrofluoric acid, concentrated sulfuric acid, and aqua regia. |

|

|

|

Niobium Materials Density:8.57g/cm3 Melting point :2468℃ Niobium and niobium alloys have excellent corrosion resistance in many corrosive environments. Its acid corrosion resistance is superior to that of zirconium but inferior to that of tantalum. Niobium also has an anti corrosion effect on some fluoride containing solutions. Niobium shows excellent corrosion resistance to inorganic acids and alkalis, and is not dissolved by aqua regia but can be dissolved by hydrofluoric acid. |

|

|

|

Tantalum Materials Density:16.6g/cm3 Melting point:2996℃ Tantalum possesses high ductility and a small coefficient of thermal expansion. Tantalum exhibits extremely high corrosion resistance. Under both cold and hot conditions, Tantalum shows perfect corrosion resistance in hydrochloric acid, concentrated nitric acid, or aqua regia. Tantalum demonstrates superior chemical resistance at temperatures below 150°C due to the formation of a 0.5-micron thick Ta₂O₅ oxide layer on its surface, which remains firmly adhered to the base material and only dissolves in HF, HCl, or concentrated alkalis under high temperature conditions. |

|

|

|

Nickel Materials Density:8.902g/cm3 Melting point:1453℃ Because of the slow rate of oxidation at room temperature, nickel is considered as a kind of corrosion-resistant metal. Nickel shows good corrosion resistance to alkali. Nickel can be slowly dissolved in dilute hydrochloric acid, dilute sulfuric acid, and dilute nitric acid, but in fuming nitric acid, it develops a passive surface layer that resists further oxidation and corrosion. Nickel alloys show high strength and certain resistance to oxidation and corrosion at high temperatures ranging from 650 to 1000 ℃. Incoloy, Inconel, Hastelloy, and Monel are families of nickel-based alloys. |

|

Leveraging our deep material expertise and over 50 years of research experience, we offer specialized metal application solutions for special corrosive environments.

UPV excels in the R&D, design, and manufacturing of high-end equipment utilizing non-ferrous metals such as nickel, titanium, zirconium, and tantalum, along with various stainless steels. We have established production lines for rare metal equipment and clean manufacturing of nuclear chemical equipment, achieving an annual production capacity of 1,000 sets of rare metal equipment.

UPV is committed to delivering efficient, high-temperature resistant, and corrosion-resistant reactors, heat exchangers, towers/columns, storage tanks, piping components, and accessories to help customers achieve the goal of increasing production, saving energy, and reducing costs.

Ensuring customer value is our top priority. Our investment in R&D, coupled with our accumulated capabilities, is the fundamental guarantee for continuously delivering value to the market and our customers. It is also the core of our sustained competitive advantage.

The list of material applications is as follows

|

Titanium materials

Density:4.51g/cm3

Melting point:1660℃

Titanium has a low density, high mechanical strength, and excellent corrosion resistance. At room temperature, titanium is resistant to dilute hydrochloric acid, dilute sulfuric acid, nitric acid, and dilute alkaline solutions. However, it is affected by hydrofluoric acid, hot concentrated hydrochloric acid, and concentrated sulfuric acid.

The most common grades of pure titanium and alloys include Gr.2, Gr.5, Gr.7, Gr.12, and Ti-6Al-4V.

The corrosion resistance of titanium is primarily due to the formation of a dense titanium dioxide film when exposed to atmospheric oxygen. While this oxide film protects titanium from acid corrosion, it offers no protection in strong oxidizing media without moisture, such as dry chlorine gas and anhydrous fuming nitric acid.

Zirconium Materials

Density:6.499g/cm3

Melting point:1852℃

At room temperature, zirconium forms a protective oxide film that prevents reactions with most atmospheric gases.

However, at higher temperatures, zirconium exhibits the following reactions:

• At 200°C, zirconium reacts with oxygen.

• At 300°C, it reacts with hydrogen.

• At 400°C, zirconium begins to react slowly with nitrogen.

• At 800°C, the reaction with nitrogen becomes more rapid.

• At approximately 500°C, zirconium reacts with carbon monoxide (CO) and carbon dioxide (CO₂).

Zirconium materials are primarily used in industries such as formic acid and acetic acid.

Zirconium is reactive metal with excellent corrosion resistance to most acids (including alkali solution, salt solution, etc.) because of its dense oxidation film.

Zirconium only undergoes severe corrosion in media such as hydrofluoric acid, concentrated sulfuric acid, and aqua regia.

Niobium Materials

Density:8.57g/cm3

Melting point :2468℃

Niobium and niobium alloys have excellent corrosion resistance in many corrosive environments. Its acid corrosion resistance is superior to that of zirconium but inferior to that of tantalum.

Niobium also has an anti corrosion effect on some fluoride containing solutions. Niobium shows excellent corrosion resistance to inorganic acids and alkalis, and is not dissolved by aqua regia but can be dissolved by hydrofluoric acid.

Tantalum Materials

Density:16.6g/cm3

Melting point:2996℃

Tantalum possesses high ductility and a small coefficient of thermal expansion. Tantalum exhibits extremely high corrosion resistance. Under both cold and hot conditions, Tantalum shows perfect corrosion resistance in hydrochloric acid, concentrated nitric acid, or aqua regia.

Tantalum demonstrates superior chemical resistance at temperatures below 150°C due to the formation of a 0.5-micron thick Ta₂O₅ oxide layer on its surface, which remains firmly adhered to the base material and only dissolves in HF, HCl, or concentrated alkalis under high temperature conditions.

Nickel Materials

Density:8.902g/cm3

Melting point:1453℃

Because of the slow rate of oxidation at room temperature, nickel is considered as a kind of corrosion-resistant metal. Nickel shows good corrosion resistance to alkali. Nickel can be slowly dissolved in dilute hydrochloric acid, dilute sulfuric acid, and dilute nitric acid, but in fuming nitric acid, it develops a passive surface layer that resists further oxidation and corrosion.

Nickel alloys show high strength and certain resistance to oxidation and corrosion at high temperatures ranging from 650 to 1000 ℃. Incoloy, Inconel, Hastelloy, and Monel are families of nickel-based alloys.

Dilute acid concentration heat exchanger group

Formic acid tower

Baffle heat exchanger

Heat energy recovery device